Optimisation of a screening tool in relation to precision

Move Innovation has in collaboration with GlycoSpot analysed and improved one of GlycoSpot's existing products. GlycoSpot wanted to optimise their SIRIUS instrument in terms of robustness, size and precision.

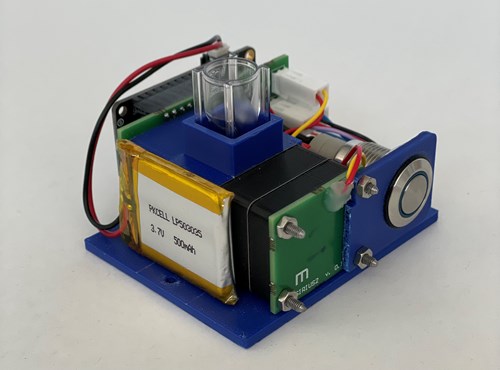

SIRIUS is a fast and simple battery-powered screening tool, also called a micro spectrophotometer, that measures enzyme activity. SIRIUS is a compact and mobile precision instrument with a spectral range of 340-850 nm. This screening tool detects colour changes depending on how many enzymes are present. SIRIUS is controlled via an app and enables an accurate measurement of the enzyme concentration, without you depending on a laboratory.

The mobile measuring device can replace laboratory tests, but why is it important to know which enzymes are present?

Enzymes are proteins that increase chemical reactions. The special abilities of enzymes can be utilised in the industry, in production of products that we use every day. Enzymes are for example used in production of bread, beer, detergent, medicines and much more. E.g. Enzymes have been added to washing powder, the enzymes can remove all the unwanted bacteria when laundry is washed by e.g. 30 degrees. Enzymes also have a great influence on the crust of the bread.

How does it work?

The way you use Glycospot's test kit is by dosing what you want to test into a liquid specially developed reagent. The reagent is placed in the SIRIUS unit which measures the concentration of enzymes.

The advantage is the mobility and speed. The test can be done on site and you’ll get the answer after a few hours, while a laboratory test you’ll have to wait for 2-3 days.

How has Move Innovation helped?

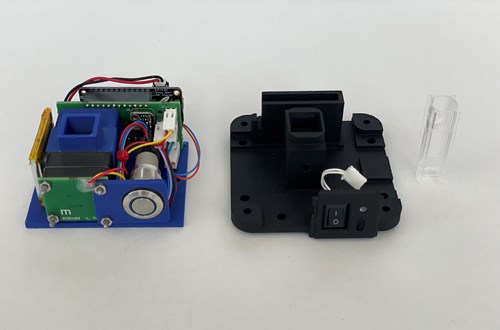

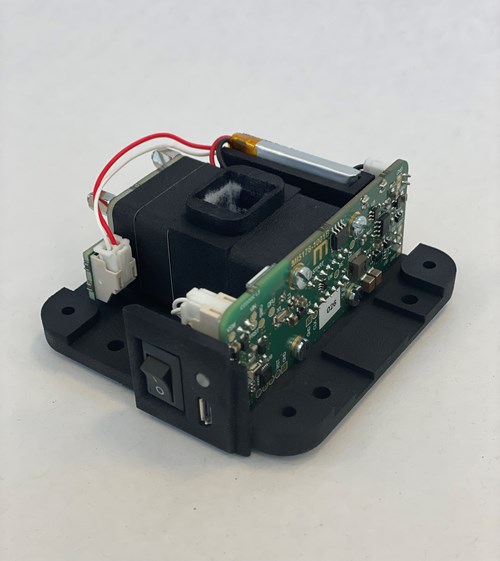

GlycoSpot had an existing product they wanted to improve. Together we analysed the existing version and developed a new version of the micro spectrophotometer. This allows an even more accurate measurement and reading of the enzyme concentration that previously had to be performed in a laboratory. We analysed the measurement process and optimised the components and software so the product became cheaper to produce and more accurate in the reading.

We designed the product with a focus on the end users, their requirements for quality in terms of choice of materials, durability and user-friendliness. At the same time, we retained the possibility of using Glycospot's existing kit.

The Process

We started with a thorough review of the existing product, where advantages and disadvantages were highlighted - a feasibility study. A number of suggestions for improvements were then prepared and tested on a prototype in collaboration with Glycospot. The mechanical design was revised to ensure a uniform production and good reproducibility. A small series was subsequently tested and approved by the University of Copenhagen, where they tested against much more expensive stationary laboratory equipment. This formed the basis for the first production series, which is produced in our production.

If you are thinking about developing or further developing a biotech or life science product, don’t hesitate to contact us.