At Move Innovation, we believe the best solutions are developed in close collaboration. We have all of our engineers gather in-house, all of our engineers are experts within different expertise. The various departments, hardware, software, design, construction and mechanics are an extension of each other and collaborate with each other on a daily basis. That’s how we ensure your solutions are looked at from different perspectives.

This is your guarantee for a well thought and thoroughly tested solution.

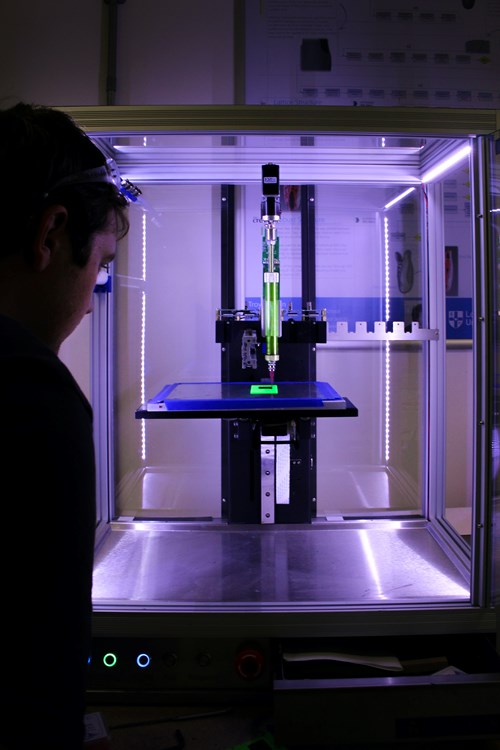

In our design, construction and mechanics department, they deal with everything from design, 3D prints, renderings and visualisation of products to mechanics and the construction of products, on a daily basis.

In the design, construction and mechanics department, we take your development through different phases, you can see these phases below

- The idea phase

- Analysis

- Conceptualisation

- Design

- Design For Manufacturing Analysis

- Documentation

The idea phase

In some projects, the Design, Construction and Mechanics Department can be involved from the beginning, and other times their skills will be put into play later in the development process.

The foundation for a successful project is a specific and detailed requirements specification, if the requirements specification is not detailed, it can affect the efficiency of the development. We start our collaboration by a workshop with you, where we clarify down to the last detail what your development should contain and how it should look.

At this workshop, we also work on turning potential problems into tangible solutions. This helps future collaboration across our various departments that contribute to the development of the product.

In collaboration with you, we will list all concepts, features and solutions for your idea and together select and rank the various solutions and features.

Analysis

We can do different types of analysis of your product as well as screening of the market, in order to assess how the product has value, or whether the market is already saturated.

This includes everything from quantitative surveys online, to qualitative surveys of and with the end user of your product, as well as other experts in the field.

We also do a technology analysis, where we assess and test how the desired technology works in practice. We assess where in your development project problems may arise based on the product's functionalities, budget and development time as well as production method.

Conceptualisation

Conceptualisation makes your product more marketable and your solution becomes more holistic and better adapted to users. When conceptualising, we often draw and design the first form of the product in SolidWorks.

For example, we can also make a mock-up, which is the first version of a physical model.

The conceptualisation provides a common form and understanding of the product. In the design, construction and mechanics department, we focus on the product's form, expression and functionality. The conceptualisation builds on the user survey and requirements specification from the idea phase.

Design

Based on the initial phases, we can design different parts, elements or your entire product.

This can, for example, be the design of the user interface on a screen, in an app or on a website, or a visualization of the product, but also the physical design of the product.

We can also do different renderings of your product.

It is important to us that your product has the desired color, surface, texture and function, to ensure this we make different models

- Functional model is a model of the product's unique functionalities

- The mock-up focuses on resembling the final product in form and finish, however the mock-up has no functionality.

When your development is ready, we create a prototype that contains the product's functionalities so the product can be tested by the target users.

We look at the users' overall experience of the product, packaging and use, and insert your product into the desired use environments. We test the product's functionality on different users and examine how it is experienced and perceived, as well as whether the product meets the requirements and specifications previously decided.

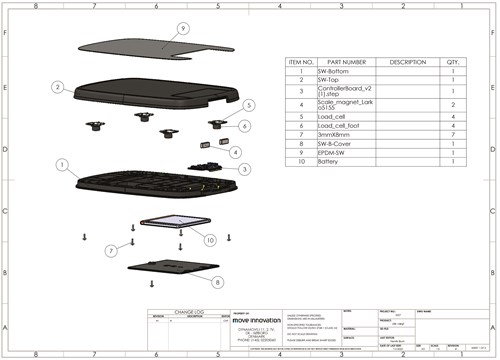

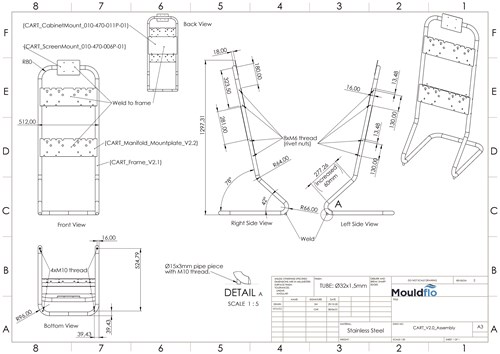

In the design, mechanics and construction department, we can produce a complete 3D drawing of your product, with dimensions in Solidworks and include a list of all the components your product contains, so your product is ready for production.

If you have an existing product that you want to optimise and improve in terms of functionality, price, production and assembly, we can also help you with this.

Design For Manufacturing

You have to make a lot of different decisions when starting the production of your product, including material selection, production technology, finish, packaging, logistics and transport. We help you make the right choices in the production phase, and choose the right production for your product. If it’s less than 2000 units per year, we are able to do the production ourselves and assemble your development.

We create a 3D file and send it to a manufacturer. Depending on the type of production technology chosen, different things must be taken into account. In the case of plastic production the 3D file must contain slip angles on all the parts and plastic suction, and so on.

Documentation

It is a good idea to document all the choices made, regarding design, mechanics and construction in the process of creation and development of your. We can prepare this for you.

In addition, we can make a written and illustrative guide for how to assemble the product. The guide is user-friendly with steps and guidance text for each stage, so your product can be assembled by others. If you have less than 2000 units per year we can assemble your product for you.

We can also prepare a manual for the end users. This user guide will show how to assemble, install and use the product. The user guide will be easy to understand, with illustrations so the end users know how to use your product.